On the market for over 20 years, patented and sold worldwide, the mechanical tapping machine designed and built by Meclostampi combines multiple features that make it simple, reliable, and, above all, cost-effective for all applications where tapping is required in the stamping cycle.

The Meclostampi tapping machine is currently exported to over 25 countries worldwide and approved by all major automotive manufacturers.

A strong point is thedirect and daily experience of using these units in our stamping department, which has allowed the reliability and performance of our tapping machines to reach remarkable achievements. Our technical department is always available to assist the customer in the design of the die, in order to suggest the most appropriate tapping solution based on the needs and operating conditions.

The same unit can in fact be used on multiple dies, which represents a unique feature in the field of tapping units for dies!

The use of tapping does not usually compromise stamping speed; in fact, under optimal conditions, it can reach remarkably high levels.

M2 – M4 250 – 300 Strokes / 1’

M5 – M6 120 – 180 Strokes / 1’

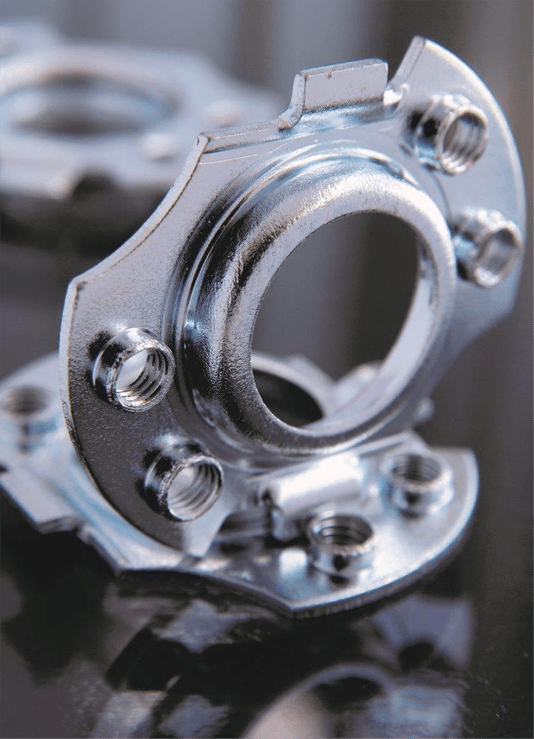

• MM 24 threading capacity from M2 to M4

• MM 56 threading capacity from M5 to M6

• MM 68 threading capacity from M6 to M8

• MM 816 threading capacity from M8 to M16

• OR 28 threading capacity from M2 to M8 with orientable tooth rack and double effect pneumatic chucking device for horizontal or inclined threading.

• MM 25 threading capacity from M2 to M5 with minimum wheelbase of 25 mm. between threads.

SPRING-LOADED OR PNEUMATIC SINGLE-ACTING SPINDLES OR PNEUMATIC DOUBLE-ACTING SPINDLES TO EXCLUDE THREADING

For technicians Of Meclostampi each work is a unique project and deserves the utmost attention, contact us for more information.

Company operating in the molding sector and of the mold making.

Where we are: Via della Fametta Strada A/1 22074 Lomazzo (CO)

Sede legale: VIA DELLE STELLINE n° 1 – 20146 MILANO | C.F/P.IVA/VAT IT 08459560960 | REA MI-2027906 | CAPITALE SOCIALE € 1.500.000

To provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.