On Meclostampi group was founded at the beginning of the 1970s on the initiative of Cav. Antonio Canobbio joined, over the years, by his sons Giuseppe and Valter.

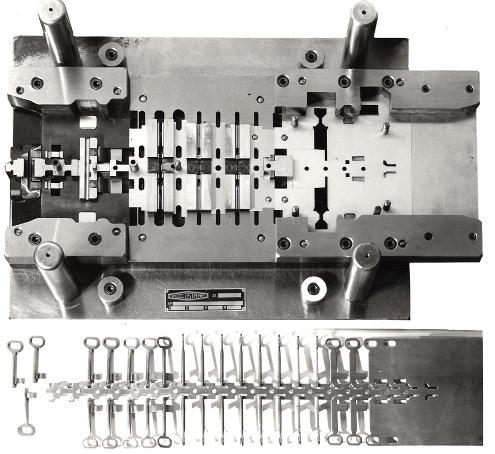

The family has thus carried on a successful industrial project in the metalworking sector specializing in the design and high precision mold construction for cold working of sheet metal.

The service currently offered covers the customer's needs 360°, starting from a possible starting from prototype activity, at the designing and producing: of equipment for series production, up to the possibility of having the printed product Completed in accordance with strict automotive standards.

Edoardo, son of Valter, after completing his university studies, he fully joined the company's management team to ensure the continuity of our organization.

The company starts its activity at Saronno, founded by Cav. Antonio Canobbio (current Sole Administrator) – Workforce: 11 people.

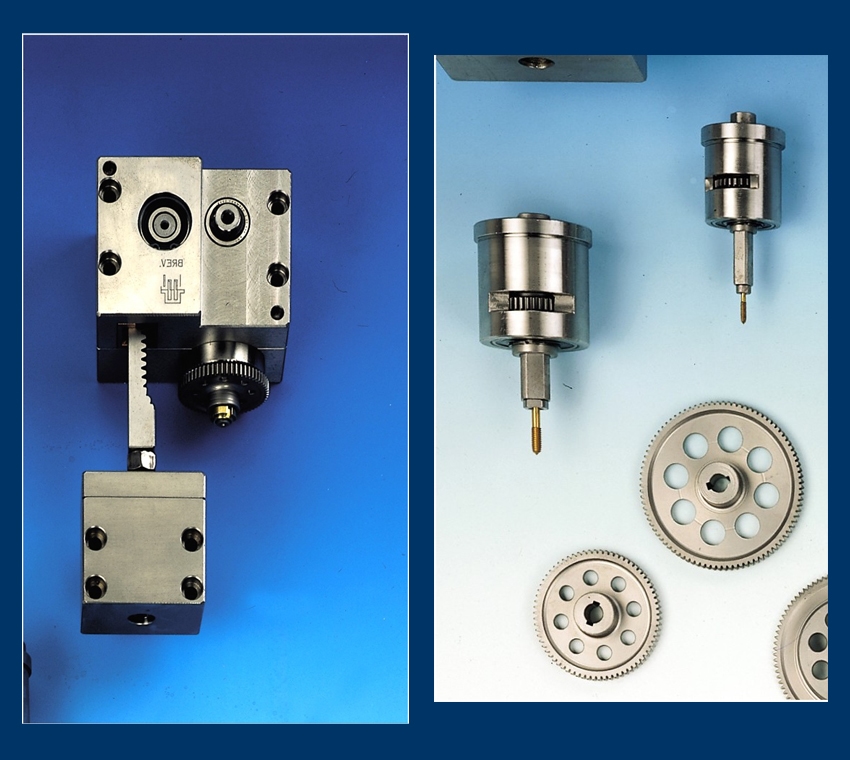

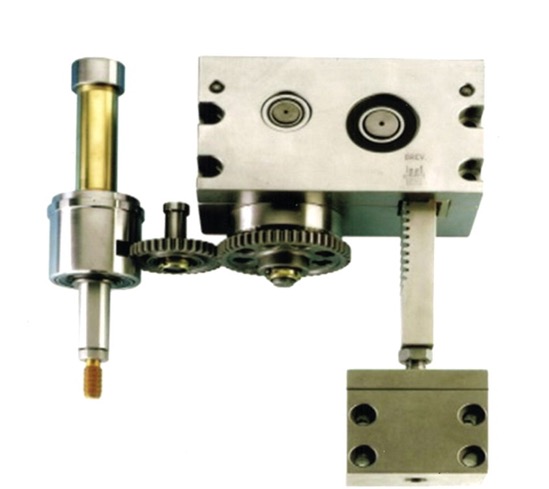

First Meclostampi threading units on the market. Thread capacity from M2 to M8.

Meclostampi threading units range is widened: now max M16; the system is patented and employed by the most important car manufacturers.

Start of new Stamping Department construction (covered area: 1.200 sq.m.); first precision presses from 60 to 200 Ton.

Quality System Certification - MECLOPRESS Molding Department

Fourth tools department expansion (now the covered area is 4.000 sq.m.).

Beginning of cooperation with PATEC Press Automation Technology Pte Ltd and first cold forming articles. Press fleet completed with 25 – 50 – 60 – 125 – 160 Ton.

First press in Italy for «cold forming» – Patec 600 Ton.; expansion of Stamping Department (covered area: 3.000 sq.m.).

Second press in ItalY for «cold forming» PATEC 300 Ton.

Launch of Meclostampi Group, born from the integration between Tool Department and Stamping Department (covered area: 7.000 sq.m.) – Workforce: 85 people.

Recertification of the Quality System for the MECLOPRESS Molding Department in accordance with UNI EN ISO 9001:2015

Installation of the second YASDA machining center

A training agreement has been signed between Meclostampi Group and CNOS-FAP professional institute of Arese for the improvement of the knowledge of trainers and students in the tool production field with consequent training courses for students in the company. // Important investments in new technologies in the Quality Control department ( introduction of 3D scanner, 3D optical machine and profilometer ).

Obtaining IATF 16249:2016 certification for the Meclopress molding department.

Installation of new stamping line with 400 Ton press and feeding/straightening line for strip width 820 mm and thickness 6 mm

Expansion of the press fleet with a new Yamada press.

Because we are serious and transparent on all fronts, for us a given word is worth more than anything else. Honoring commitments and meeting deadlines and agreed terms is simply our standard work philosophy.

Because we always step up, making our clients' problems our own. We respect everyone’s opinions and always offer our know-how with humility and great professionalism, learning from our mistakes.

Because we do our job with PROFESSIONALISM AND PASSION always putting our heart into it. We are a company with solid roots, well-capitalized, and ready to face the challenges the future holds.

For technicians Of Meclostampi each work is a unique project and deserves the utmost attention, contact us for more information.

Company operating in the molding sector and of the mold making.

Where we are: Via della Fametta Strada A/1 22074 Lomazzo (CO)

Sede legale: VIA DELLE STELLINE n° 1 – 20146 MILANO | C.F/P.IVA/VAT IT 08459560960 | REA MI-2027906 | CAPITALE SOCIALE € 1.500.000

To provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.